- Products

- Air Compressors & Air Tools

- Climate Control

- Compaction Equipment

- Concrete Cutting Tools & Equipment

- Concrete and Masonry

- Demolition & Excavation

- Electrical & Mechanical

- Fasteners and Anchoring Adhesives

- Floor Protection

- Generators and Welders

- Hand Tools

- Heaters

- Janitorial and Office Supplies

- Jobsite Protection

- Ladders & Storage

- Lighting & Lighting Accessories

- Man Lifts

- Material Handling Equipment

- Power Tools

- Pressure Washers & Pumps

- Safety Gear

- Safety Products

- Saws

- Surface Preparation

- SEASONAL PRODUCTS

- Rentals

- Air Compressor and Air Tool Rentals

- Climate Control Rental

- Compaction Rentals

- Concrete Equipment Rentals

- Demolition & Excavation Equipment Rentals

- Concrete Floor Grinder Rentals

- General Construction Equipment Rentals

- Generator Rentals and Welder Rentals

- Heater Rentals

- Light Tower Rentals

- Man Lift Rentals in Massachusetts and Rhode Island

- Material Handling Equipment Rentals

- Pressure Washer & Pump Rentals

- Saw Rentals in New England

- SEASONAL PRODUCTS

- Products

- Air Compressors & Air Tools

- Climate Control

- Compaction Equipment

- Concrete Cutting Tools & Equipment

- Demolition & Excavation

- Electrical & Mechanical

- Floor Protection

- Generators and Welders

- Construction Heaters

- Construction Ladders, Staging, & Storage

- Construction Lighting

- Man Lifts

- Material Handling Equipment

- Industrial Janitorial and Office Supplies

- Pressure Washers & Pumps

- Construction Safety Products

- Construction Safety Gear

- Surface Preparation

- Building Protection

- Diesel Accessories

- Zero Emissions

- Rentals

- Air Compressor and Air Tool Rentals

- Climate Control Rental

- Compaction Rentals

- Concrete Equipment Rental

- Demolition & Excavation Equipment Rental

- General Construction Equipment Rental

- Generator Rentals and Welder Rentals

- Construction Heaters Rental

- Light Tower Rentals

- Man Lift Rentals

- Material Handling Equipment Rental

- Pressure Washer & Pump Rentals

- Saw Rentals in New England

- Concrete Floor Grinder Rentals

- Zero Emissions Rentals

- Repairs & Used

- Parts

- Blog

- Services

- Resources

- About Us

- Contact Us

Sales & Rental of Construction | Industrial Equipment & Supplies

You are here:

Top Machine Tools for Precision Engineering You Need to Know About

In the realm of precision engineering, the significance of machine tools cannot be overstated. These sophisticated devices are the backbone of modern manufacturing, enabling engineers to create intricate components with unparalleled accuracy. As industries continue to evolve, the demand for advanced machine tools that enhance precision, efficiency, and productivity has surged. This article delves into the top machine tools that are essential for engineers aiming to achieve high standards in their work.

With a variety of options available, selecting the right machine tool can be critical to achieving desired outcomes in both design and production. From CNC machines to lathes and milling machines, each type plays a unique role in the manufacturing process, contributing to the precision engineering landscape. Understanding the features and capabilities of these tools will equip professionals with the knowledge necessary to make informed choices that fit their specific needs and applications. As we explore these essential machine tools, we will highlight their importance in driving innovation and maintaining competitive advantages in the fast-paced engineering sector.

Table of Contents

[Hide]

Key Factors Defining Precision Engineering in Machine Tools

Precision engineering is critical in the manufacturing sector, significantly influencing the performance and quality of machine tools. Key factors defining precision engineering encompass accuracy, repeatability, and reliability. According to a report by the International Federation of Robotics, precision machining processes have seen a growth of approximately 10% annually, highlighting the increasing demand for accuracy in automated systems. This emphasizes the necessity for tools designed to minimize tolerances and enhance output consistency, shaping the standards by which manufacturers operate.

Moreover, machine tools are not only evaluated on their ability to cut materials but also on their capacity to maintain precision under various operational conditions. Factors such as thermal stability, vibration damping, and the design of tool paths directly influence production quality. A study conducted by the Manufacturing Technology Centre suggests that improvements in these areas can lead to a 15% increase in machining efficiency and a 20% reduction in waste, underscoring the importance of innovation in the development of precision engineering tools. As manufacturers strive towards enhanced productivity, continual investment in research and development within machine tools remains essential for achieving superior precision standards.

Overview of Essential Machine Tools for Precision Engineering

Precision engineering relies heavily on a variety of machine tools that are vital for producing parts with high accuracy and fineness. Among the essential tools, CNC (Computer Numerical Control) machines are particularly noteworthy, as they offer automated control of machining processes. These machines can perform milling, turning, and drilling tasks with remarkable precision, significantly enhancing productivity while reducing human error. The ability to program complex geometries allows engineers to produce intricate components that meet stringent specifications.

Another critical category of machine tools includes lathes and milling machines. Lathes are primarily used for producing cylindrical parts, while milling machines are designed for creating flat surfaces and detailed features on a workpiece. Both tools are fundamental in transforming raw materials into finished products and play a crucial role in prototyping and mass production. Additionally, tool grinders and electric discharge machines (EDMs) are essential for sharpening cutting tools and performing intricate shapes, respectively. Each of these tools contributes uniquely to the precision engineering landscape, highlighting the diverse capabilities needed for sophisticated manufacturing processes.

Top Machine Tools for Precision Engineering

| Machine Tool | Type | Precision Level | Applications | Material Capability |

|---|---|---|---|---|

| CNC Milling Machine | Milling | 0.01 mm | Complex parts, prototypes | Metals, Plastics |

| CNC Lathe | Turning | 0.02 mm | Axial components | Metals, Wood |

| EDM Machine | Electrical Discharge Machining | 0.005 mm | Die making, intricate details | Conductive materials |

| Laser Cutting Machine | Laser Cutting | 0.1 mm | Sheet metal, signage | Metals, Plastics |

| 3D Printer | Additive Manufacturing | 0.1 mm | Prototyping, complex structures | Plastics, Composites |

Top CNC Machines and Their Applications in Precision Engineering

In the realm of precision engineering, CNC (Computer Numerical Control) machines have become indispensable tools, revolutionizing manufacturing processes with their unparalleled accuracy and efficiency. According to a 2022 market research report by Mordor Intelligence, the global CNC machine market was valued at approximately $70 billion and is projected to grow at a compound annual growth rate (CAGR) of about 7% from 2023 to 2028. This robust growth highlights the increasing reliance on CNC technology across various industries, including aerospace, automotive, and medical device manufacturing.

The applications of CNC machines in precision engineering are vast and diverse. These machines facilitate complex shapes and designs that traditional machining tools cannot achieve, thus enabling the production of intricate components with exacting tolerances. For instance, a study by MarketsandMarkets indicated that the precision machining technology segment is anticipated to account for nearly 60% of the overall CNC machine market share by the end of the forecast period. Industries are harnessing CNC milling, turning, and grinding to enhance productivity while reducing material waste and operational costs, thereby improving their bottom line.

Furthermore, the integration of advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) into CNC systems is poised to further enhance their capabilities. According to a report by Technavio, the adoption of smart manufacturing technologies, including CNC automation, is expected to drive operational efficiencies with a potential increase in productivity by up to 30% in the next five years. As precision engineering continues to evolve, the importance of CNC machines will only grow, providing manufacturers with the tools they need to stay competitive in a challenging market.

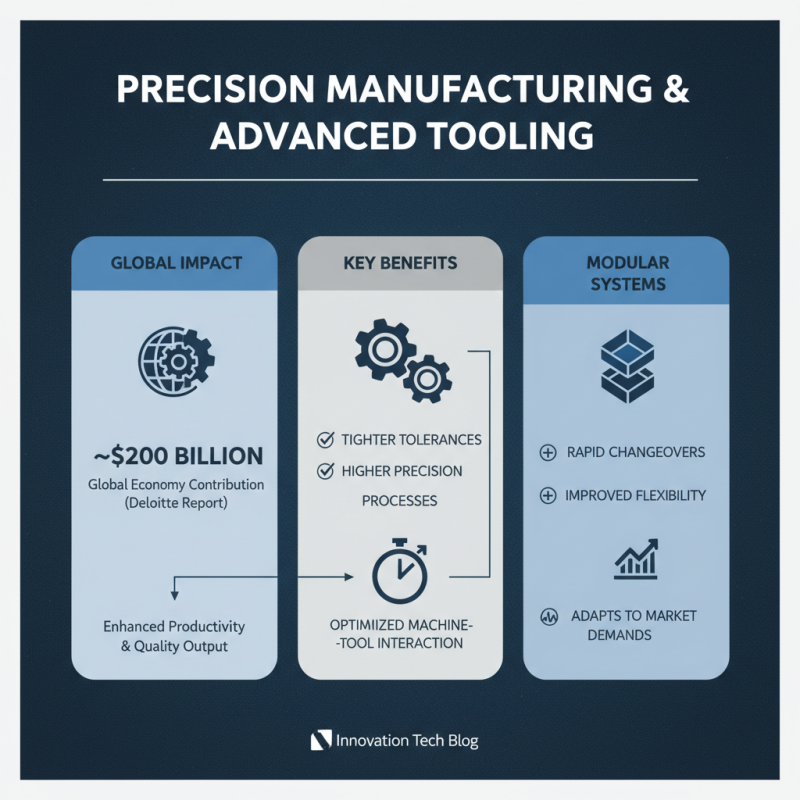

The Role of Tooling Systems in Precision Manufacturing

In the realm of precision manufacturing, tooling systems play a pivotal role in enhancing productivity and ensuring high-quality output. According to a report by Deloitte, precision engineering contributes approximately $200 billion to the global economy, underlining the significance of advanced tooling systems that streamline processes. These systems are designed to optimize the interaction between machinery and tools, enabling manufacturers to achieve tighter tolerances and higher precision. The adoption of modular tooling systems, for example, allows for rapid changeovers and improved flexibility on the shop floor, which is crucial in meeting the demands of ever-changing market conditions.

Furthermore, the integration of advanced technologies, such as computer numerical control (CNC) and automation, has revolutionized tooling systems within precision engineering. A study by McKinsey indicates that manufacturers that embrace these technologies can increase their operational efficiency by up to 30%. Tooling systems equipped with smart sensors provide real-time feedback on performance, enabling predictive maintenance and reducing downtime. As companies increasingly focus on lean manufacturing and minimizing waste, the importance of adaptive and precise tooling systems becomes more pronounced, establishing them as essential components in achieving competitive advantage in the industry.

Innovations in Precision Measurement Tools for Enhanced Accuracy

In the rapidly evolving field of precision engineering, innovations in measurement tools are paramount for achieving enhanced accuracy. According to a report by market research firm Mordor Intelligence, the global precision measurement tools market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth underscores the increasing demand for precision in manufacturing processes, where even the slightest deviation can lead to substantial issues in product quality and operational efficiency.

Advanced measurement technologies, such as laser scanning and digital measurement systems, are at the forefront of this transformation. Laser scanning allows for rapid and accurate dimensional analysis, providing engineers with real-time data to make informed decisions quickly. Furthermore, the integration of artificial intelligence in measurement tools has led to the development of systems that can learn and adapt, resulting in higher accuracy rates and reduced human error. According to a study by Grand View Research, the growing adoption of these technologies is expected to enhance productivity and precision in engineering projects, reflecting the industry's commitment to continuous improvement and innovation in quality control mechanisms.

Top Machine Tools for Precision Engineering

Related Posts

-

2025 Top 5 Air Compressors for Air Tools You Should Consider

-

2025 Guide: How to Choose the Best Electric Heaters for Your Home

-

How to Choose the Right Concrete Tools for Your DIY Projects: Expert Tips & Trends

-

Top 5 Essential Hand Tools Every DIY Enthusiast Should Own

-

Unlocking the Power of All Tools for Everyday Productivity and Creativity

-

Exploring the Evolution of Shop Tools from Handheld Gadgets to Smart Technology

© Copyright - Pro Tool & Supply - Site by SVM E-Marketing Solutions - Sitemap

- Privacy policy